Your needs come first with a custom system

Rather than trying to fit your application to an existing laser model, Microtrace begins by considering your performance objectives and specifications for an ideal mark. With your needs at the forefront, a custom laser system is configured and fully optimized for you—whether you need units integrated directly on your production line, or a stand-alone marking station.

Our dedicated team of expert engineers can address difficult-to-mark products that others may have deemed impossible. With micromarking and micromachining lasers, mark virtually any material without jeopardizing the integrity of your product, including:

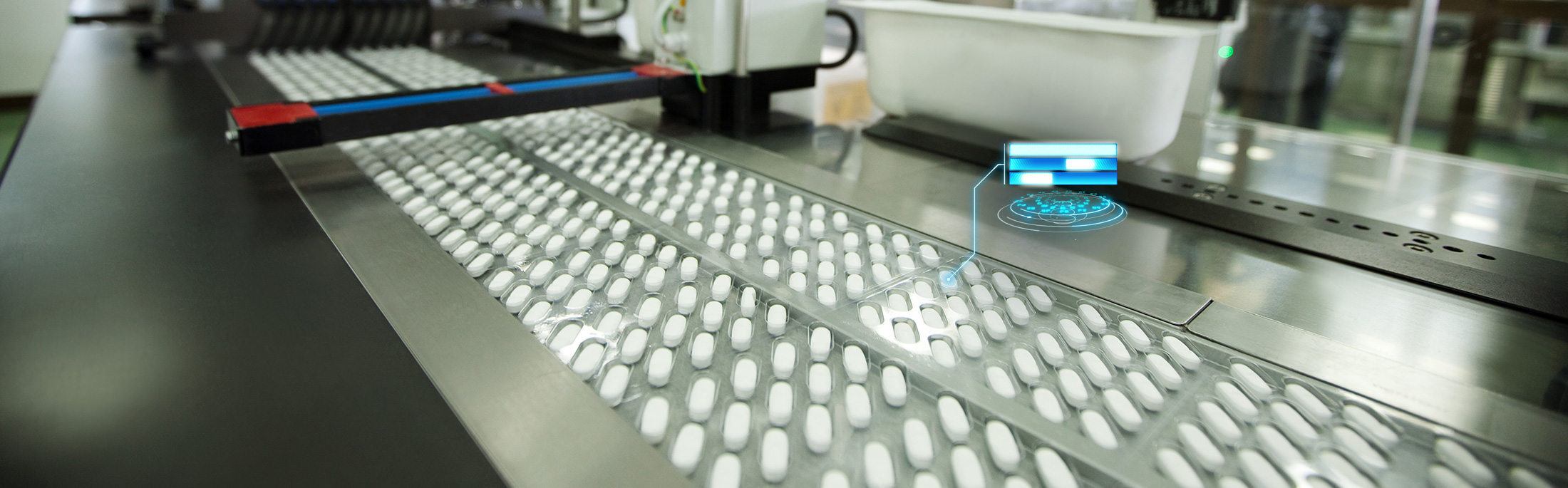

- Pharmaceutical tablets

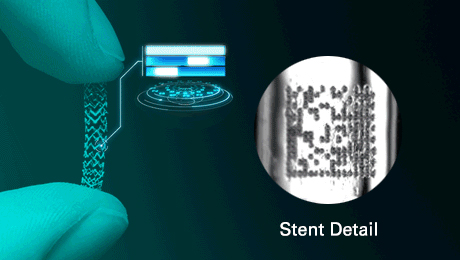

- Barcodes on medical devices

- Invisible barcodes on eyeglasses

- Small wires in aerospace applications

- Logos on precious stones

Let us handle part marking to skip stressors

Alternatively, if you want microscopic part marking but aren’t ready to make a capital investment, we can do the product marking for you. We can mark nearly any substrate or surface as small as a sub-micron—for reference, a human hair is about 100 microns.

Microtrace’s laser-marking support team has expertise in a variety of laser types, power levels and configurations such as excimer, CO2, Pico, Femto, ND YAG and fiber optic.

Get help evaluating components of your production needs

In addition, Microtrace can help you prepare for the right laser system. Use our laser division as your complete research and development center to evaluate lasers, additives and material for laser marking. Or use it for your scale up for ongoing production needs.